Data Center Power Chains: AC vs. DC

In a data center, the power chain is the sequence of infrastructure equipment that distributes power from its source all the way to the IT devices.

Most data centers use alternating current (AC) power, though telecommunications companies typically use direct current (DC) power. There are pros and cons to each, and they require different equipment.

Understanding your data center power chain is important because it helps you ensure redundancy and uptime, intelligently perform capacity planning, and simplify troubleshooting.

What is the Difference Between AC and DC Power Data Centers?

The key differences between data centers that utilize AC or DC power are:

- Current direction. With AC power, the flow of electrons is constantly changing directions back and forth. The current changes 60 times per second in North America and 50 times per second in Europe. With DC power, the flow is linear in one direction.

- Transformers. Voltage can be easily transformed with AC power. The power comes into the facility at 600V or 480V and a transformer steps it down to 208V or 120V. DC power chains do not include transformers.

- Power interruption. AC power data centers use UPS units and batteries to provide backup power in the event of a main power failure. The AC power is converted to DC power for storage, and during an outage, it Is converted back to AC and distributed downstream. DC power data centers use power plants with batteries that store energy for emergencies, and no conversion is required.

- Standardization. AC power is the current standard. DC power does not have the same standard for voltages and connectors that AC does. There is also less options on the market for DC power equipment such as air conditioning and fire protection systems.

- Space. DC power equipment is less complex and takes up less physical space than AC power equipment.

- Scalability. DC power systems are more modular and can be easily scaled up by adding more battery strings as the load increases.

- Run time. The run time provided by DC battery strings is greater than the run time provided by a UPS for the same load.

- Load balancing. AC power may be in three-phases which requires load balancing.

- Efficiency. Converting power from AC or DC to the other results in power loss and heat. DC power systems require less conversions, so they are typically more energy-efficient.

What Objects Are in a Typical AC Power Chain?

A typical data center with an AC power distribution system will include the following objects, roughly in this order:

- Utility feed. The main source of power during normal data center operations is the feed coming directly from the local power utility company.

- Transformers. Transformers reduce the voltage of incoming power to a level that is appropriate for the next piece of equipment in the power chain.

- Automatic transfer switch (ATS). Downtime is expensive and must be kept to a minimum. In the event of a power failure, the ATS seamlessly transitions to an emergency power source. Once power is restored, the ATS returns the load back to the utility feed.

- Generators and fuel tanks. During a power outage, diesel generators are a common emergency power source that the ATS transfers the load to until the utility feed is restored.

- Switchgears. The power from the utility feeds into the switchgear which splits and distributes the power into any number of outgoing circuits that power various critical and non-critical loads of the facility.

- Uninterruptible power supplies (UPS). UPS units store energy that is temporarily deployed during an outage. When there is a power failure, it can take 10 to 15 seconds for the generator to reach full power. During that time, UPS units provide emergency power until the backup power can support the load, and their batteries can typically provide power for up to 30 minutes.

- Floor power distribution units (PDUs). Floor-mounted PDUs act as a bridge between the facility’s primary power and the data center. They transform and distribute the incoming power to groups of remote power panels or busways.

- Remote power panels (RPPs). RPPs distribute, control, and monitor the power going to groups of racks with IT equipment.

- Busways. An alternative to RPPs, busways are located above rows of server racks.

- Rack PDUs. Rack PDUs are power strips that are installed in pairs in each individual server rack. To provide redundancy, each IT device is plugged into an outlet on each rack PDU which are part of separate power paths. Rack PDUs can be basic (also known as “dumb”) or intelligent. Depending on the model, intelligent rack PDUs can be monitored, metered (at the inlet or outlet), and or switched.

What Objects Are in a Typical DC Power Chain?

A typical data center with an DC power distribution system will include the following objects, roughly in this order:

- Utility feed. As with an AC data center, the power for a DC data center comes from the local utility company as AC power.

- Power plants. In the facility, power plants consist of a rack with a rectifier and batteries. The rectifiers convert the incoming AC power into DC power and charge the battery strings that keep the plant running for a period of time during an outage until the utility power is restored.

- DC bays. Battery distribution fuse bays (BDFBs) and battery distribution circuit breaker bays (BDCBBs) split the incoming power from the power plant into multiple feeds for downstream equipment. The key difference between them is that BDFBs protect against overloaded circuits while BDCDBBs protect against overloads and short circuits.

- Fuse alarm panels. Fuse alarm panels (FAPs) are similar to rack PDUs in an AC power chain. They are mounted in racks and provide power distribution and protection to the IT devices within those racks.

Track and Manage Your Data Center Power Chain with DCIM Software

Whether you have an AC or DC power chain in your data center, you need to understand the objects in your power chain and know the health of your system.

That’s where Data Center Infrastructure Management (DCIM) software can help.

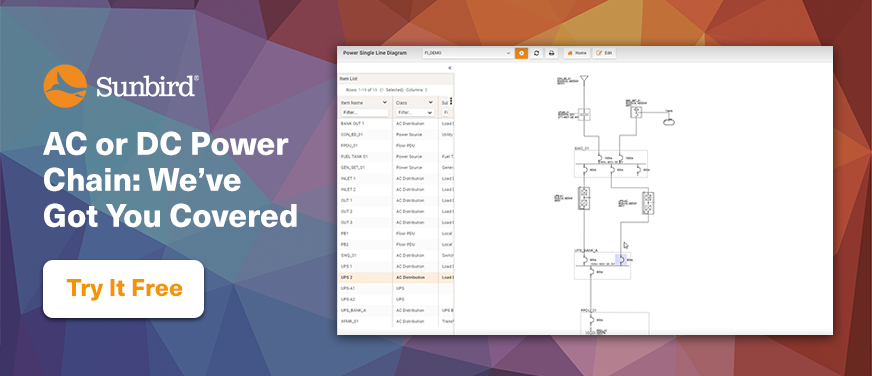

With modern DCIM software, you can track all the items in your AC or DC power chain from the power source down to the compute devices and track their electrical characteristics and interconnections. This makes it easy to understand the power capacity and load at any node in the system.

DCIM software also automatically generates dynamic and interactive single-line diagrams that help you visualize your power chain in a single pane of glass. You can track the utility feed, generator and fuel tanks, transformers, load devices, UPS units, AC panels, floor PDUs, DC power plants, and DC bays, track all draw-out breaker and disconnect switches, track breaker status, and see a details panel for each node that includes budgeted and actual values for voltage, current, power rating, highest/lowest phase, and more.

Want to see how Sunbird’s award-winning DCIM software simplifies power chain management? Get your free test drive now.